Reduce Sheathing Waste

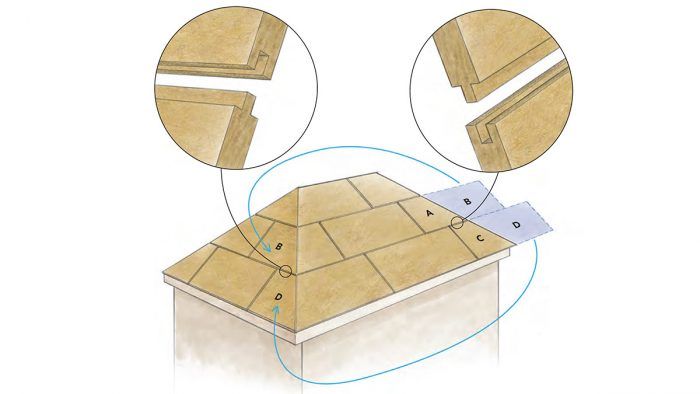

When installing tongue-and-groove sheathing on a hip roof, change the orientation of the tongues and grooves as needed so that you can reuse cutoffs.

I’m building a 24-ft. by 32-ft. bungalow with a hip roof, and the engineer specified tongue-and-groove (T&G) roof sheathing. Installation is going well, but I’m ending up with a lot of waste sheathing because I can’t use the leftover cutoffs when I start and end at the hips. Is there a solution?

—Travis Wentz, Des Moines, Iowa

John Spier, a builder on Block Island, R.I., replies: I live and work in a coastal high-wind area, and we’ve been using T&G roof sheathing for about 25 years. I probably built two or three hip roofs or dormers with T&G sheathing before I figured out the waste problem. Intuitively, I had always assumed that the tongues should face uphill, to keep from potentially trapping water. Then I realized that if I am taping the seams or covering the whole roof with underlayment, the water-trap idea is moot; any water that is trapped during construction will dry to the inside. So now I switch the orientation of the sheathing on alternate sides of the roof, tongue-up to tongue-down, and all of my cutoff trapezoids are usable with minimal waste. Incidentally, the same concept applies to roofs with valleys.

I searched a couple of manufacturers’ websites for some guidance on this but didn’t find any references to orientation. And online forums showed a variety of opinions, from people who orient to prevent water intrusion, to those who feel that groove-up is easier to sledgehammer (with a block) into position.

Drawing: Dan Thornton

From Fine Homebuilding #317

RELATED STORIES

Fine Homebuilding Recommended Products

Ladder Stand Off

Peel & Stick Underlayment

Hook Blade Roofing Knife