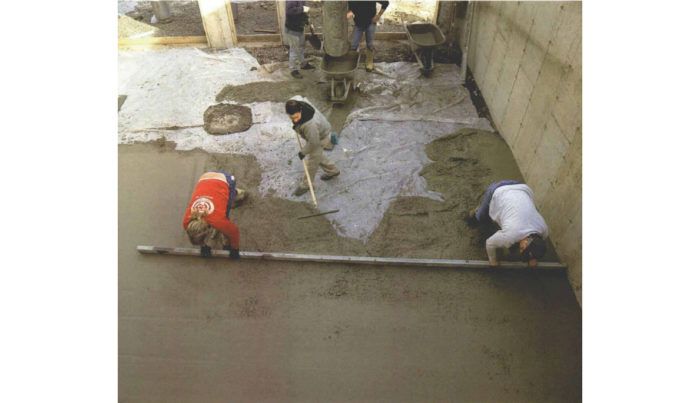

Pouring Concrete Slabs

Tips on ordering, placing, screeding, floating and finishing.

Synopsis: Here’s an explanation of how a truckload of wet concrete becomes a flat, smooth slab. A sidebar offers suggestions for placing concrete in less than ideal weather conditions.

Liquid stone. It’s an image you might think describes placing concrete, and to some extent, it does. But there’s more to it than backing up the ready-mix truck, opening the spigot and letting the concrete flow out until the forms are full.

The applications of concrete are almost limitless, but here I’ll focus on residential slabs. About half of the new homes currently built in the United States start with full-basement foundations, and virtually all of these basements have concrete floors. For the most part, these floors consist of 4 in. of concrete placed over 4 in. or more of crushed stone. Concrete floors in garages are similar, except they are sometimes reinforced with wire mesh or steel. But whether it’s a basement or a garage slab, the way you place the concrete is the same.

Ordering concrete

Concrete is sold by the cubic yard, and calculating the amount you need is simple: length times width times depth (in feet) divided by 27 equals cubic yards. Most concrete trucks max out at 9 yd., and if your floor will require more than nine (the average floor uses about 19 yd.), tell your supplier to allow about an hour to an hour and a half per truckload so that all the trucks don’t arrive at once.

But a word of caution. Running out of concrete is like running out of champagne at a wedding: If you can’t get more real soon, you’re headed for trouble. Don’t be stingy with your concrete estimate. You’re a lot better off with half a yard left over than a quarter yard short.

Once you’ve told your concrete supplier how much concrete, you’ll have to tell them what kind. Concrete is made up of four basic ingredients: cement, sand, stone and water. Depending on the proportions of the ingredients, the strength can vary considerably. Compressive strength, measured in pounds per square inch (psi), is the method used to evaluate the performance of a given mix. Generally speaking, the higher the cement content, the higher the compressive strength. Most residential concrete has a compressive strength between 2,000 psi and 3,500 psi.

You’ll also need to specify the slump, or the wetness, of the mix. A slump of 4 to 5 is about right for slabs, whereas a slump of about 2 to 3 is normal for piers, which don’t need to be worked, so the concrete can be stiffer.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Original Speed Square

Plate Level

Smart String Line