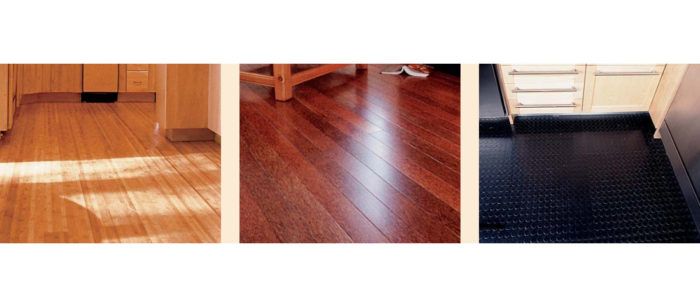

Kitchen Flooring Choices

From old standbys like hardwood to new contenders like laminates, the choices are daunting. We evaluate the pros, cons, and costs.

Synopsis: A kitchen designer compares and contrasts different flooring materials that are suitable for kitchen use, including laminates, solid and engineered wood, vinyl and linoleum sheet goods, and tiles, ceramic and stone tile, along with unusual choices such as bamboo, rubber, and stainless steel.

In the world of building materials, genetic engineering is a constant. The products may look traditional, but underneath their skins lie bonded, laminated, foamed, recycled and reconsidered cores. Nowhere is this ferment of product development more robust than in the flooring business. Floors have been to the lab and come back smarter, stronger and so much easier to care for. Even linoleum, the flooring a previous generation mopped and waxed on a regular basis, is back in an easy care formulation. New products such as snap-together laminates have the old-time look of fumed oak, or not. You also can find Italian laminates the color of mint gelato, with a sprinkling of burlap for a non skid surface. So what’s best for a kitchen? Consider appearance, practicality, comfort, “green-ness,” antiallergen properties, resale value, maintenance, individuality, ease of installation, ease of removal, longevity, historical suitability and price.

Laminates: The look of the familiar, and more

In Europe, our source for many a savvy design tip and trend, homeowners often take their kitchen cabinetry with them when they move. More and more often, they are taking their kitchen floors as well. Snap-together laminate, a removable, portable flooring, has interlocking edges that join the pieces together into a single unit.

Like engineered woods, laminates are multiply sandwiches. The visible layer is a photographic image topped with a tough, clear layer of melamine that takes the wear. Products range from 9/32 in. to 1 ⁄2 in. thick. Laminate should be installed over a flat subfloor, which can be either a layer of plywood or even an existing vinyl or tile floor, as long as it is in sound condition.

Laminate flooring is a rising star. It has loads of positive features and few minuses. In just five years, it has captured 4% of the entire flooring industry.

As interest and demand grow, so too do the number and quality of products. Most laminate floors mimic wood or tile. But other patterns and textures are emerging. ABET Laminati, which produces the Parq Color series of wood pattern laminates (45 choices), also makes Fiber Floor, a textured product with a matte finish. Available in 12 muted shades, the slightly rough surface results from the burlap-bag fibers used in its manufacture. The sacks previously held coffee beans, so there are some bean bits in the flooring, which add flecks of darker color. Seems perfect for the kitchen floor.

Installations in the North American market used to require that planks be glued together. Now 20% of the laminate-flooring products in this market are glueless: They snap together with clever locking mechanisms tight enough to keep out liquids. These products, more than those requiring glue, target the do-it-yourself market.

Even systems requiring glue use it only to adhere one tongue-and-groove plank to another, never to the subfloor. A laminate kitchen floor is meant to float atop the subfloor, not be glued or nailed to it. Some manufacturers produce several quality levels. Get the best you can for your kitchen.

For more photos and details on kitchen flooring, click the View PDF button below.

Fine Homebuilding Recommended Products

The New Carbon Architecture: Building to Cool the Climate

A Field Guide to American Houses

All New Bathroom Ideas that Work