Installing a Sheet-Vinyl Floor

Whether flat-lay or coved, use a felt-paper pattern for best results.

Synopsis: This article explains how to make templates from building paper to accurately cut sheet vinyl flooring. The author covers both flat-lay floors, in which flooring ends at the wall line, and coved corners.

People still call it linoleum, even though it isn’t, and the chances are good that the floors in your bathroom and kitchen are covered with it. It’s properly called resilient flooring, and it also turns up in the family room, workshop, and utility porch—any place where a durable, low-maintenance, and affordable floor is a requirement.

Resilient flooring is available in a wide price range, from as little as $3 a square yard to over $30 a yard, and it comes in colors and designs that will suit just about anybody’s taste. Along with the outlay for supplies, you can figure an equal amount for the installation labor. This article is about how to install resilient flooring in two different ways. One is the relatively easy flat-lay method. The other is the more complicated coved style that used to be common with linoleum floors.

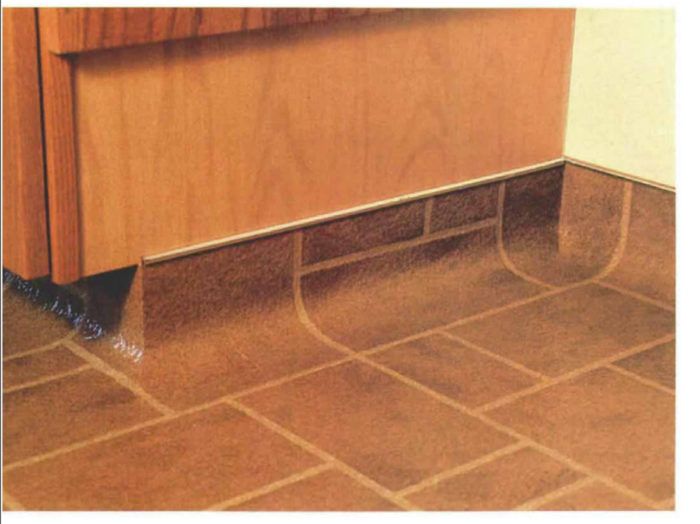

Flat-lay is the term for a floor that meets the wall at a 90° angle. This junction is covered by a baseboard or a toe molding. A coved floor requires a little more material than a flat-lay floor, and it wraps right up the wall, where it is finished with a J-section trim piece called cap metal. The floor-to-wall intersection is backed with radiused blocking called cove stick. At inside and outside corners, the flooring is mitered—it’s the floor mechanic’s version of the carpenter’s crown-molding problem. A coved floor is more difficult to install than a flat-lay floor, but I think it looks classier, and it’s easier to keep clean at the perimeter.

There are two basic types of resilient floors available today: sheet goods, which come in 6-ft., 9-ft., 12-ft., and 15-ft. widths; and tiles, which are usually 1-ft. square. Most sheet goods and tiles are made of either vinyl compositions or pure vinyl. I’m going to concentrate on sheet vinyl because it’s the most popular, and it comes in the greatest variety of colors, grades, and designs.

Vinyl-tile floors follow the same basic installation procedures as sheet-vinyl floors, and the boxes of tile usually include easy-to-follow instructions. But I think vinyl-tile floors have one serious drawback: they have lots of seams for water or dirt to invade. This can be a serious problem, especially in wet locations with wood subfloors. Don’t get me wrong—I’ve seen properly maintained inexpensive vinyl-tile floors over wood substrates that have lasted for many years, but this is the exception and not the usual case.

Estimating materials

The rule of thumb is to lay out the floor with the fewest seams, and with the least amount of waste. There are only two possible directions to run the vinyl, and one is usually better than the other.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Original Speed Square

Smart String Line

100-ft. Tape Measure