Soundproofing a Floor With a Wood Ceiling Below

Remodeling pro Mike Guertin offers two approaches for controlling noise between the basement and first floor of a house.

I’m trying to install sound insulation between my first floor and basement, and I don’t want to use drywall. Part of my goal in this is soundproofing the floor. The house is essentially all wood except for the concrete basement floor. The floor joists between the basement and first floor are 2x10s on 16-in. centers. On top of that are two layers of ⅝-in. plywood glued and nailed, with oak hardwood flooring above that.

I’m planning on installing mineral-wool sound-control batts between the joists. I’m also going to install knotty pine 1×6 boards for the ceiling. My question is: what can I use between the joists and the knotty pine to minimize direct sound transmission? Do you have any recommendations?

— George Gull

Mike Guertin Responds:

Adding the sound-control batts will help reduce the sound transmission through the air between the floor surface and the ceiling below. The transmission through the joists is an even more important pathway to address. So don’t skimp or you may be unhappy with the results, and you only have one chance to get things right.

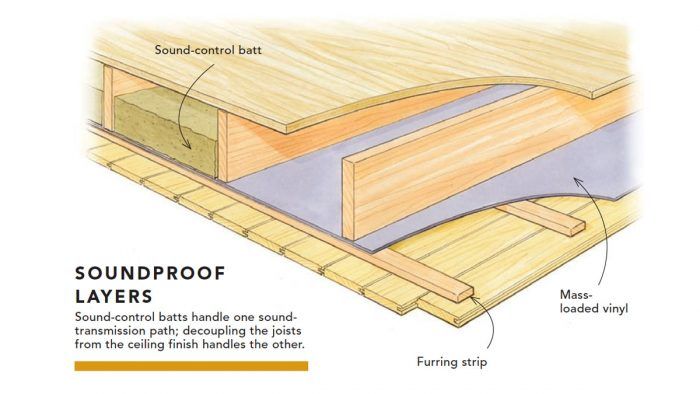

When it comes to soundproofing floors through the joists, there are two basic approaches. One: decoupling the framing members from the ceiling material, and two: adding mass (density). These approaches work best when used in combination.

Some type of furring or strapping is the simplest way to decouple the ceiling from the joists. Resilient metal channel is the go-to for the best performance for the cost. You’d need about 850 linear ft. for the ceiling, which would be about $300.

But using resilient channel will require installing the tongue-and-groove pine with screws rather than nails. And this is a step some may not want to take to get a soundproof floor. An alternative to resilient channel is 1×3 wood furring.

It doesn’t soundproof the floor as well as resilient channel, but you can nail the ceiling planks into it. And if it’s available at your local lumberyard, it should be a little more economical than the resilient channel.

A common and cost-effective way to add mass is to install ⅝-in. drywall. But if you want to avoid drywall, you can use an alternative like mass-loaded vinyl. Mass-loaded vinyl is an approximately ⅛-in.-thick roll material that you can attach to the bottom of the joists to help dampen sound.

Use it in combination with wood furring strips by first applying the mass-loaded vinyl to the joists and then the furring over it. The vinyl will cost about $0.75 per square foot more than using drywall.

If cost is a concern, you can eliminate the addition of mass and just go with decoupling. In that case, wood furring can be applied over adhesive-backed, 1¼-in.-wide by ¼-in.-thick foam-gasket material to help isolate the furring from the joists a little better than with direct wood-to-wood contact.

From Fine Homebuilding #284

RELATED STORIES

- Soundproofing: A Successful Hybrid Approach

- Cheap Tricks for Soundproofing

- Soundproofing: Lessons from a Custom-Built Sound Studio

Got a Tip?

Do you have any great tips like this one on soundproofing floors? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

Published May 8, 2019.

Fine Homebuilding Recommended Products

Foam Gun

Nitrile Work Gloves

Great Stuff Foam Cleaner

View Comments

Sonopan is also a great way to reduce any type of sound.