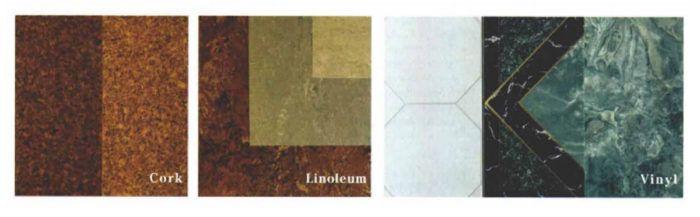

Choosing Resilient Flooring

Because of environmental concerns, cork and linoleum now compete with vinyl as attractive, durable flooring alternatives.

Synopsis: Vinyl has been the resilient floor of choice in bathrooms and kitchens for years. This article also explores the benefits of cork and linoleum flooring, and makes the case for using these alternatives in other rooms.

“All-natural,” a catchphrase of the ’90s, is used to describe everything from soft drinks to bath soap. But resilient flooring? In a market dominated by synthetic vinyl, cork and linoleum are enjoying dramatic increases in popularity, due in large part to the fact that they’re manufactured primarily from natural and recyclable products.

Historically, resilient flooring has been used almost exclusively in kitchens and baths, and for good reason. Those rooms normally encounter splashing water, shaving cream, and spaghetti sauce, and are not normally wise places to have carpet.

Ceramic tile is hard and cold, and it has those infernal grout lines. Wood floors are prone to water spots and swelling if moisture isn’t cleaned up right away. Resilient flooring, because of its proven performance in difficult environments, has been king in these applications. It never needs refinishing as does wood, and your kids won’t get splinters in their feet when they slide through a room.

Cork is a renewable resource

The building industry is sometimes castigated for using up limited natural resources. The supply of cork, though, is not likely to be depleted any time soon. The cork oak tree has been regularly harvested since at least the Roman Empire. After the tree is 30 to 40 years old, and every nine to 10 years thereafter, the cork oak tree is literally skinned alive. This harvesting process continues for 100 to 150 years on each tree. The cork oak originally was found in the Mediterranean region. Most of the world’s cork now comes from Spain, Algeria, Morocco, and especially Portugal, which accounts for approximately 88% of all harvested cork.

For cork flooring, raw cork is ground, mixed with wood glue, baked, and made into cubes or into rolls about as long as 150 ft. As it comes off the production line, it is called agglomerate cork. The cork is cut to size, then finished and readied for distribution.

Cork floors are practical

Cork is actually the floor of choice in Japan, and it enjoys huge popularity in Germany and Australia. I’ve been a flooring contractor for 13 years, and when we moved into our house, we chose to install cork floors in the entry, family room, kitchen, and baths. With three teenage children, a dog, and little time for maintenance, our family has found cork to be a logical choice.

Available in thicknesses ranging from 3.2 mm to as thick as 8 mm, cork is comfortable underfoot and has thermal insulating properties. A cork floor installed on a concrete slab is much warmer than ceramic or vinyl. Heavy furniture sinks slightly into a cork floor, but when the furniture is removed, the cork springs back to, or close to, its original form. Also, cork absorbs sound.

Cork flooring is available in tiles or in rolls, and in different finishes, including sanded, vinyl coated, prewaxed, and polyurethane-coated. Some colors available are light brown, medium brown, dark brown, two-toned, and striped.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

A Field Guide to American Houses

All New Kitchen Ideas that Work

A House Needs to Breathe...Or Does It?: An Introduction to Building Science