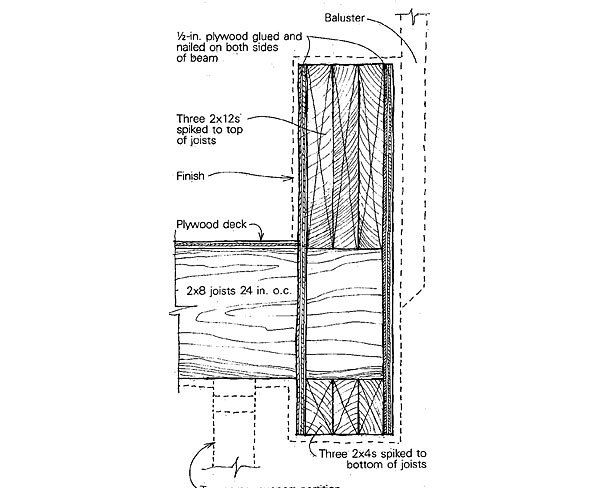

Built-up beam

The house I recently worked on has a balcony that spans 23 ft. over the living room. The plans called for a 6-in. by 22-in. by 24-ft. beam to carry the balcony, but such a beam proved hard to find—even a laminated version. We considered using a steel I-beam, but the rough framing was” nearly complete, and a soggy site suggested a difficult delivery. So builder Charlie Callahan and I worked out this simple sitebuilt plywood box beam as an alternative.

First we set the balcony floor joists on a temporary partition, as shown in the drawing. Then we spiked together three 2 x 12s on top of the joists, forming a balcony curb. Three 2x4s were spiked together under the joists for the bottom chord of the beam. Since our clear span was 23 ft. and we needed 6 in. of bearing at both ends, we cast about for 24-ft. framing lumber. We were fortunate to find some locally, so we didn’t need to splice any chords. However, splices are permissible in this kind of beam if they are staggered, and glued as well as nailed.

To connect the top and bottom chords of the beam, we covered both sides with 1/2-in. plywood, nailed and glued. We used sheets 22-1/2 in. by 8 ft. on the outside face of the beam. On the inside face, we covered the spaces between the joists with pieces that were 22-1/2 in. square. The beam is wrapped with T&G oak as a finish.

This beam is exceptionally strong, and it acts as one with the balcony joists to resist twisting. It was also fast and easy to build in place. We engineered the beam with the help of American Plywood Association’s “Plywood Design Specification,” Supplement #2. Single copies are available free from APA, 7011 S. 19th St., Tacoma, Wash., 98466.

Frank Lee, Baltimore, MD

Fine Homebuilding Recommended Products

Protective Eyewear

N95 Respirator

Angel Guard Deck Demon