All About Roof Trusses

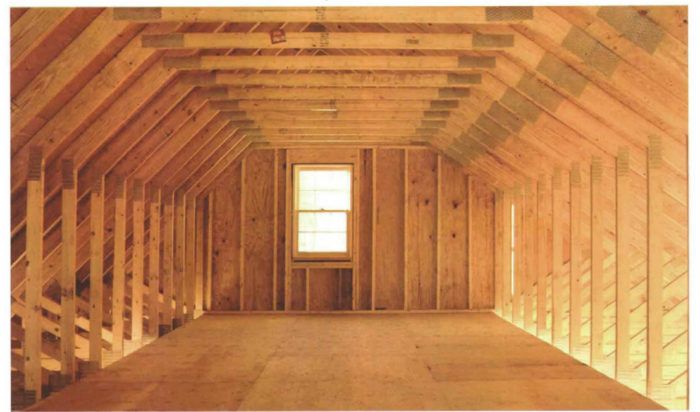

Trusses can be used to frame even complex roofs, but they must be installed and braced properly.

Synopsis: Roof trusses offers a speedy alternative to conventional framing and are used increasingly on houses of many architectural styles. This article discusses various types of trusses, where they can be used, and how they should be handled on the job.

Not too many years ago, you didn’t find roof trusses in homes with anything more elaborate than a gable roof. Thanks to computers and sophisticated design software, that era is long gone. Name just about any roof these days — gable, hip, saltbox, mansard or gambrel — and it can be framed with engineered trusses. Precision-made from dimensional lumber and metal connectors called truss plates, prefabricated trusses have revolutionized residential roof construction over the last three decades. Roofs on more than 75% of all new houses in the United States are built with trusses instead of with conventional 2x framing, and it’s not hard to understand why.

Trusses give builders a bigger bang for their buck. Truss-framed roofs can be erected more quickly and with less skilled labor than stick-built roofs. Closure against the weather is faster because trusses and roof sheathing often can go up on the same day. Trusses mean more flexible floor plans because they can span longer distances without interior bearing walls than conventionally framed roofs. Trusses are efficient in their use of lumber. Where a conventionally framed roof might require 2×8 rafters spaced 16 in. o.c., for instance, trusses for the same roof might be made entirely of 2x4s and spaced 2 ft. o.c. and use 15% to 25% less wood.

When you’re used to beefy 2x rafters, trusses take a little getting used to: They look spindly. But once they are set and braced properly, trusses are stronger than stick-framed roofs. A truss is really a series of triangles, a geometric shape that is difficult to distort under load. Unlike common rafter stock, much of the material that goes into roof trusses is machine tested for strength and is held together by engineered truss plates sized for the loads they will carry.

For all their advantages, though, roof trusses must be handled differently than regular 2x rafters. They have strength only in a vertical position and can’t be banged around a job site like a 2×12. Proper installation techniques and bracing are critical, and trusses can’t be modified in the field without radically altering their strength.

How does the cost of a trussed roof compare with a conventionally framed roof? The answer depends on the complexity and the size of the roof. But because trusses use less material, they look more attractive as the cost of framing lumber continues to rise, and high-quality framing stock becomes harder to get. The only real way to know is to price both options, but keep in mind that a conventionally framed roof takes more skill to build.

Shapes and sizes

Trusses are as varied as the houses they go on and can be combined to create complex roof shapes. Some trusses look similar — the king post, queen and Fink trusses, for example, all have the same shape — but can be distinguished by the signature web patterns inside. Because each web design distributes force differently, these trusses are rated for different loads and spans even though they look very much alike.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

11" Nail Puller

Hook Blade Roofing Knife

Stabila Extendable Plate to Plate Level